We Build Molds that Work

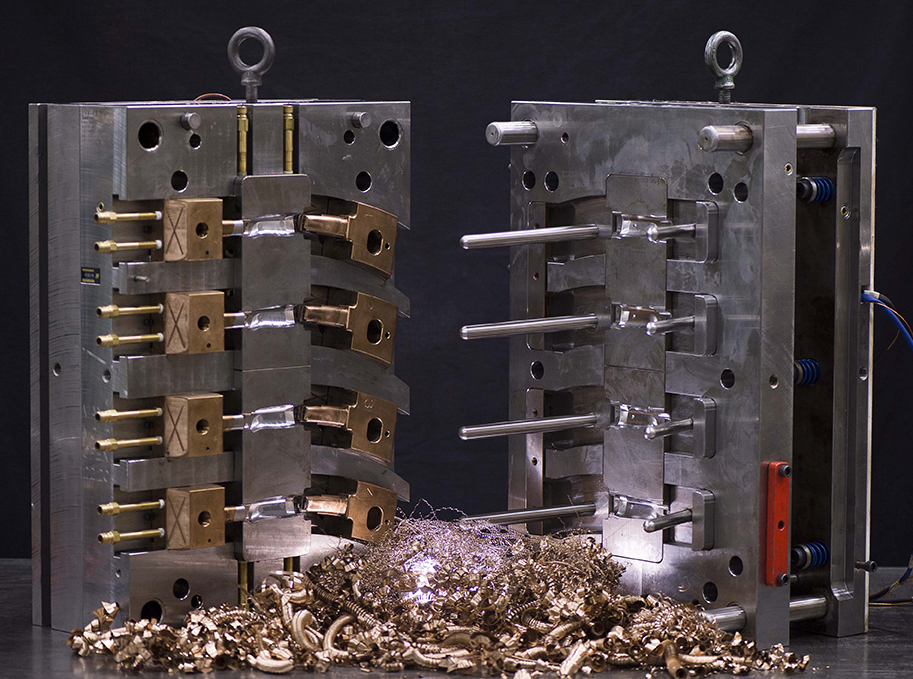

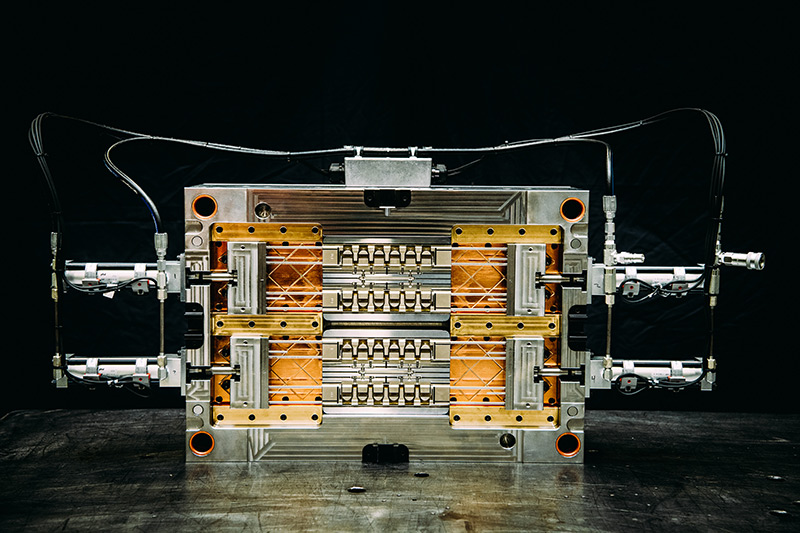

Our motto is, “We build molds that work,” and we stand behind this promise. Pleasant Precision specializes in the design and build of complex, high quality and high precision tooling. Our focus is to provide the customer with quality parts at reduced lead times through cost effective and lean manufacturing processes.

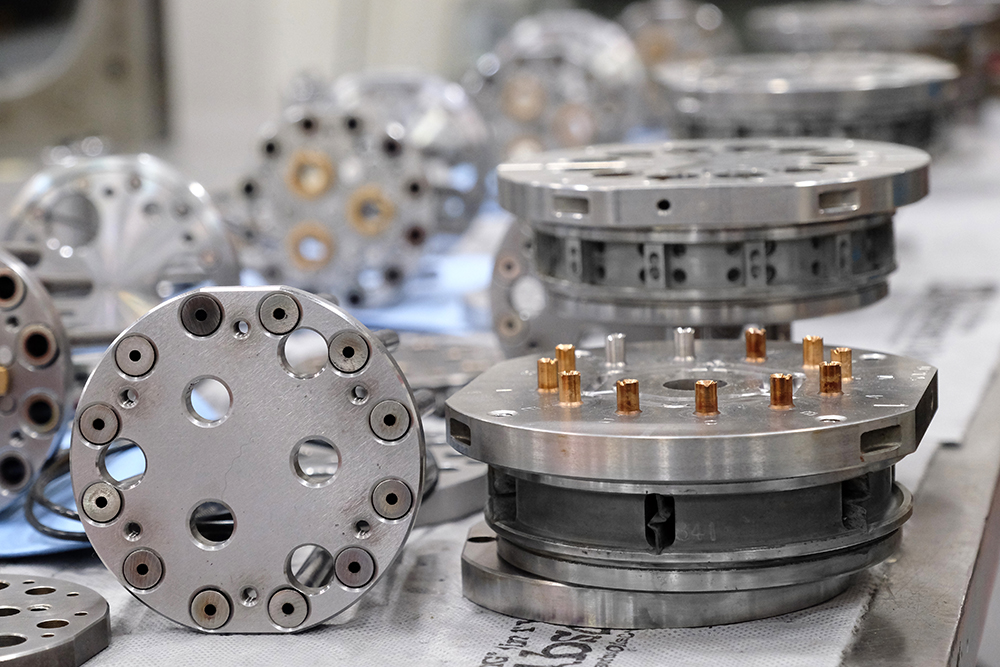

Our expertise allows us to build quality, multi-cavity tools while maintaining total consistency of tight tolerances among each cavity. With experience in building injection molds in the automotive, medical, electrical, aerospace, and consumer good markets, we have proven our ability to design and manufacture premier tooling.

Expertise

- Round Mate® Molds

- High Cavitation

- Turn-key Tooling Systems

- Modular Molds

- Shuttle/Insert

- Hot Runner & Cold Runner

- Complex Unscrewing

- Low Cost Alternatives

- ISO 9001:2015 Quality Management System

Design & Engineering

- Comprehensive Design Services

- Tools designed in solid models

- Creo 3.0

- Design for Manufacturability

- Rapid Prototyping

- Precision Tolerance

- Reverse Engineering

- Mold Flow Analysis

- Concept Feasibility

What are the lean manufacturing advantages of Round Mate®?

Click here to learn more Mold Repairs & Maintenance

Mold Repairs & Maintenance

We understand that having even one cavity down in your mold means reduced production. Our molding production is fully supported by our state-of-the-art ISO 9001:2015 QMS certified tooling facility. Our repair team will ensure your mold is running at full production. We also utilize IQMS to track and maintain regular PM schedules to avoid downtime.

Design changes are completed with the guidance of our engineering team. We incorporate high-speed machining and EDM, followed by metrology verification and tool validations, to verify that all mold repairs are accurate and reliable.