Engineering Data & Design Guides

Streamline your production and tool manufacturing processes with our helpful engineering data and advice. The design guides below are technical engineering data provided to assist in designing the Round Mate® System. Please call 800-860-3974 if additional assistance is required.

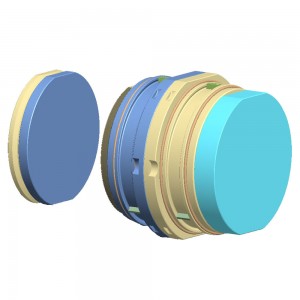

Round Mate® Overview

This document provides an overview of the vast array of solutions that can be accomplished using the Round Mate® system, and provides you with tangible cost justification for how Round Mate® can improve your bottom line in both mold making and molding.

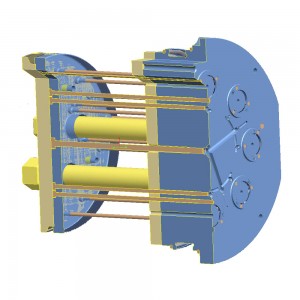

Ejection Methods

No matter your design intent for part removal, Round Mate® can adapt. Ejector pins, ejector sleeves, delayed ejection, accelerated cores, stripper disc and single or double stripper plates can all be implemented into the Round Mate® system.

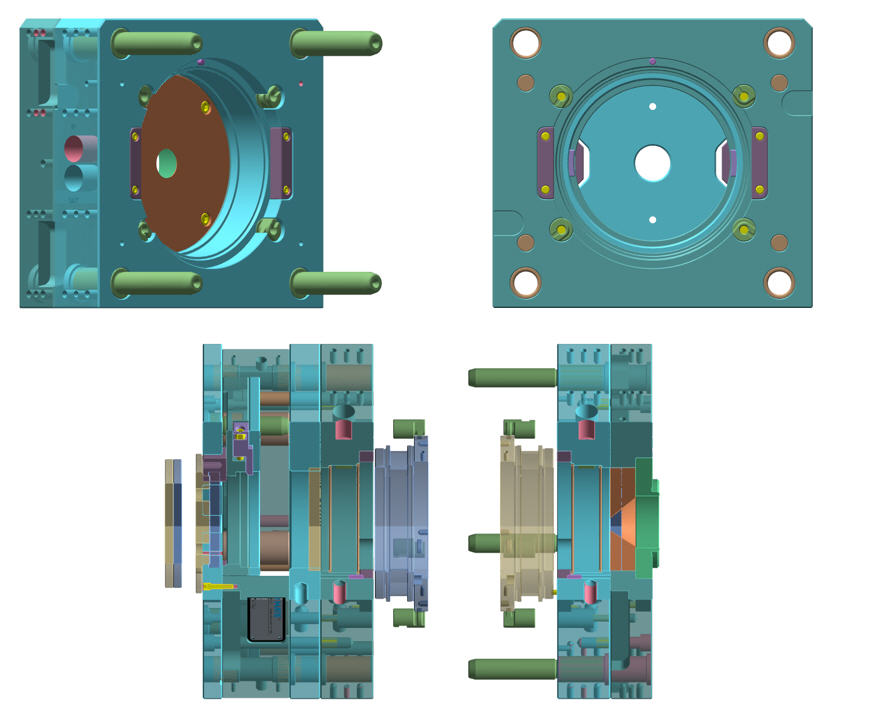

Round Mate® Mold Makers Guide

This guide is used to assist the mold maker in grinding our round inserts, installing support pillars, installing water dams, adding core retainer plates and setting up the correct stack heights to the required qualifications for single position and multi-position insert series.

Runner and Gating

Any gating method that can be used in standard mold making can be achieved with Round Mate – parting line runner to a sub or tab gate, hot sprue bushing, center sprue, multiple gated part and hot manifold systems are just a few of the ways parts can be gated. Round Mate® also offers a three plate system that allows the gate drop to be in line with the press sprue.

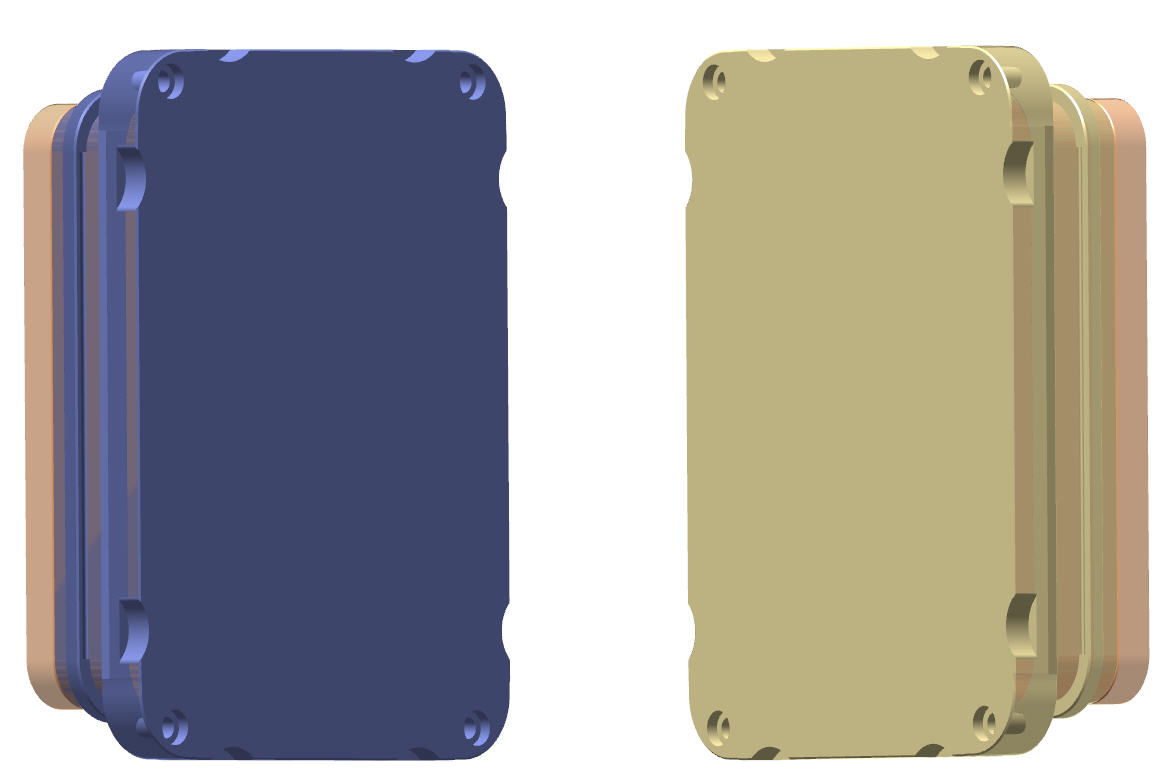

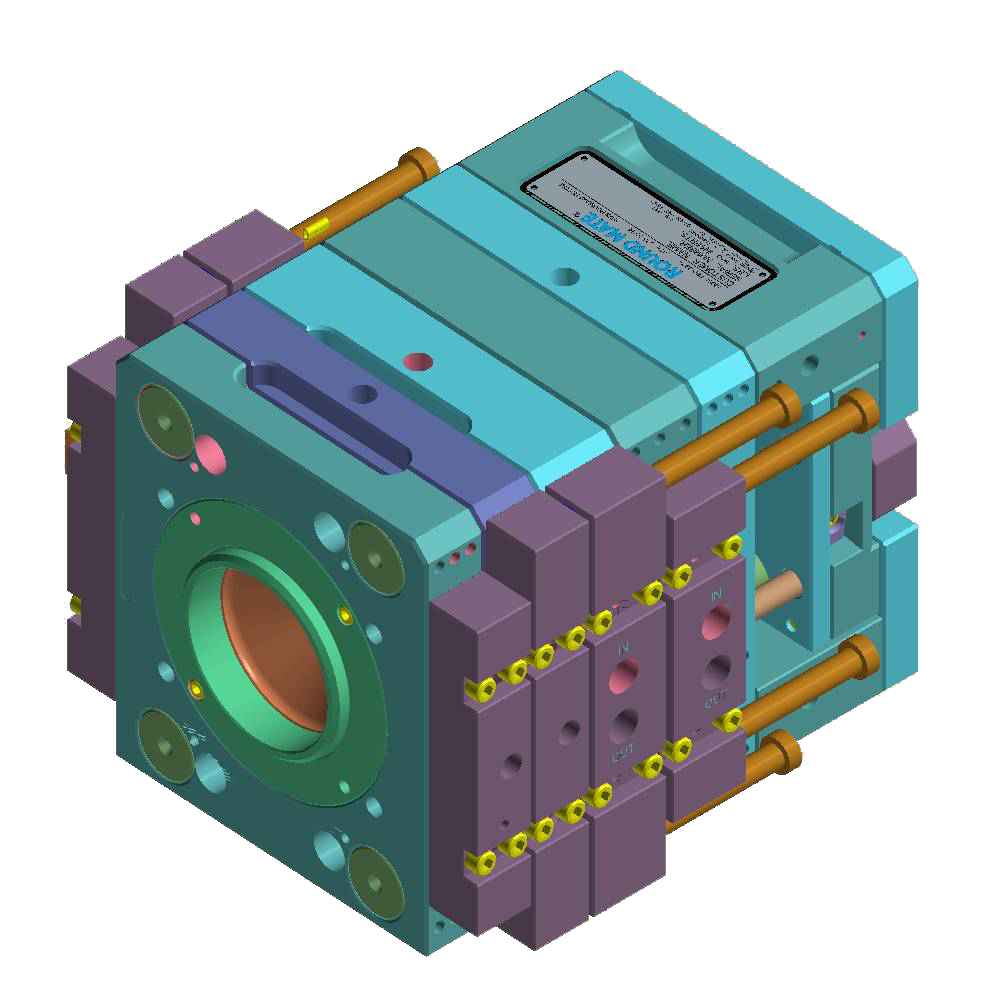

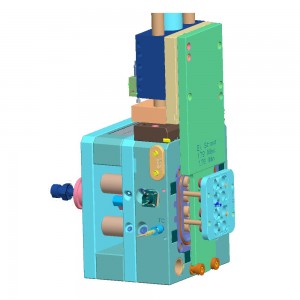

System 2 Guide

Does your part design require more space? Does your mold maker prefer to work on rectangular pieces of steel? Does your part require slides? These are only a few of the reasons you may be interested in System 2. The master frame retains all of the features of our round series – inserts change from the face of the frame, water jackets are coated for rust resistance, all stainless steel mold plates and more – but other options are available to you if your needs require something different than the original Round Mate.

Mold Actions

Grooves, snaps, threads, latches and other types of undercuts can easily be handled by the Round Mate® system. All of these can be accomplished within the industry-leading 10 minute mold changeover time.

Three Plate Overview

The most requested option to Round Mate® systems was for a quick change three plate system. Round Mate® has listened and delivered! We have engineered our three plate system to easily replace the fixed half of your existing master frame. The choice is yours; purchase a complete new three plate frame or only the fixed half to add to an existing frame.

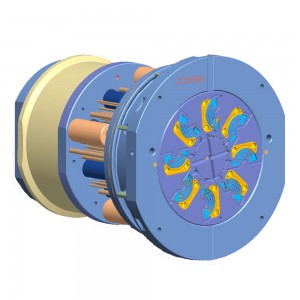

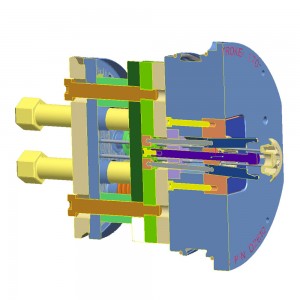

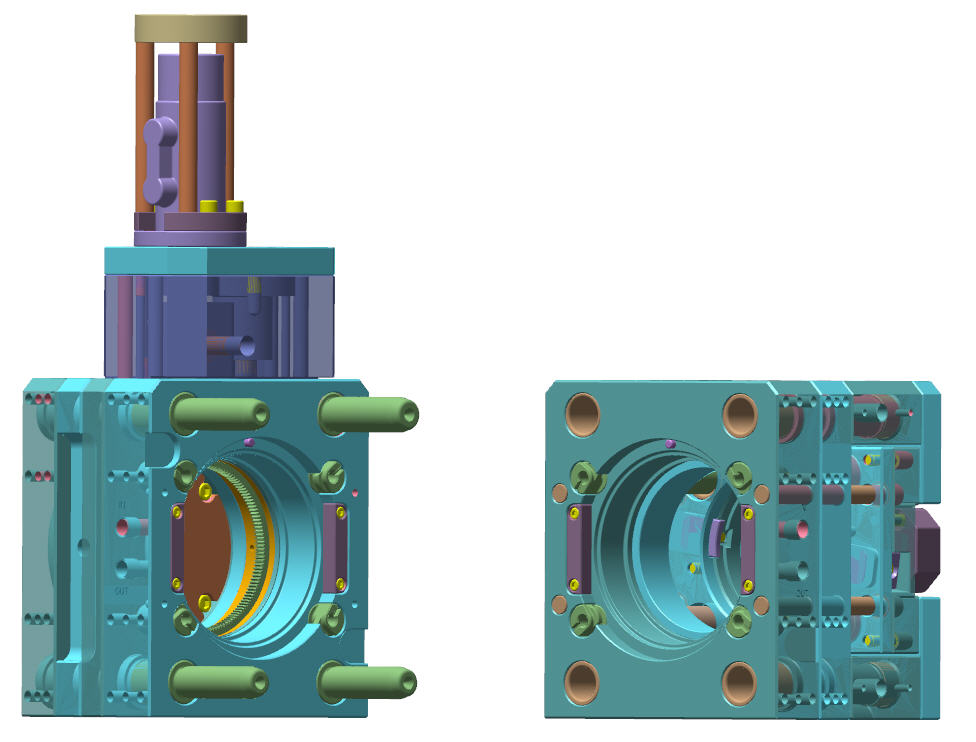

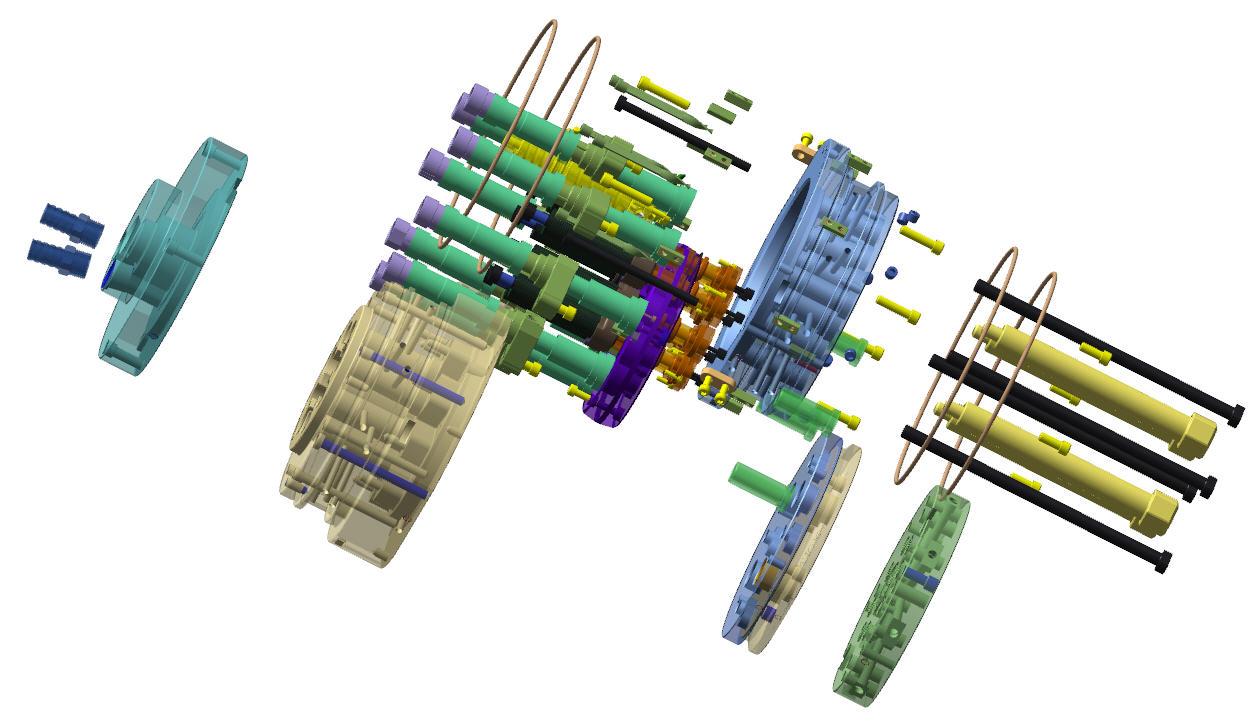

Unscrewing Overview

Unscrewing molds are complicated, but they don’t have to be. Our unique round inserts make unscrewing molds simple. A rotating ring gear around our inserts allows the designer the flexibility to drive the cores by either a direct gear drive or by idler gears. This arrangement allows for infinite design flexibility. Our system also incorporates air return on the cores which helps to prevent damage to the last thread when the core releases from the part. It is available with either a hydraulic or electric motor.

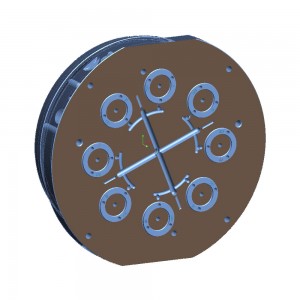

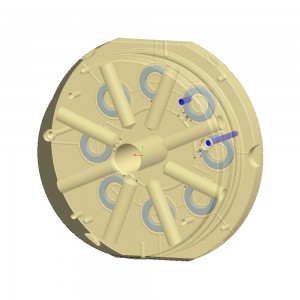

Part Layout

Round Mate® can handle any of your desired cavity placements – In the center, arrayed, rectangular, side-by-side, in the solid or in cavity inserts. Round Mate’s® unique round shape lends itself perfectly to interlocking parting lines, and we keep extra height inserts in stock to accommodate taller parts.

Custom Options

Round Mate® can adapt to multiple needs and applications. This section provides initial designs for Round Mate® single and dual unscrewing, various heated insert combinations, multiple stripper plate options, valve gating diagrams, hot bushings, and 2 position master frame configurations. Round Mate® is a dynamic modular mold system.

Temperature Control

The patented water jacket design allows for uniform temperature control through the entire insert, eliminating hot or cold spots. Additional plates can be added to the insert set to further enhance your control flexibility. An optional manifold plate can be added to the master frame to provide direct core pin cooling. Round Mate® offers a patented fluid turbulation water baffle that installs easily into a drilled hole and snaps into location.

Maintenance and Insert Installation

Round Mate® can adapt to multiple needs and applications. This section provides initial designs for Round Mate® single and dual unscrewing, various heated insert combinations, multiple stripper plate options, valve gating diagrams, hot bushings, and 2 position master frame configurations. Round Mate® is a dynamic modular mold system.